|

|

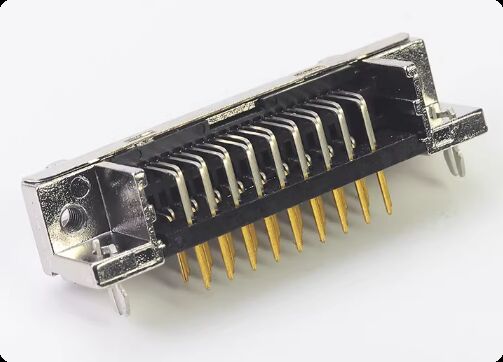

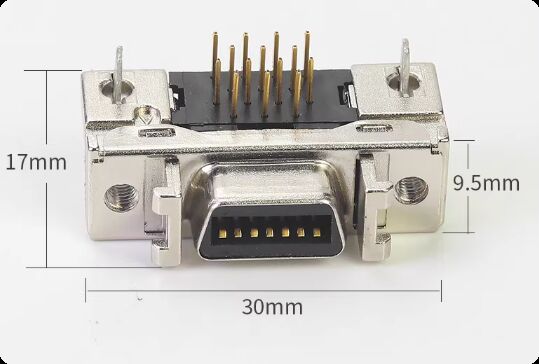

Gold-plated SCSI PCB Connector with Moog Gender for 1000V Servo Motor Applications

|

उत्पाद विवरण:

भुगतान & नौवहन नियमों:

|

| माउन्टिंग का प्रकार: | पैनल माउंट/केबल माउंट | इन्सुलेशन प्रतिरोध: | 10पिन |

|---|---|---|---|

| संपर्क चढ़ाना: | सिल्वर पिन गोल्डेड पिन | सामग्री: | धातु/प्लास्टिक |

| परिचालन तापमान: | -40℃ से +105℃ तक | समाप्ति प्रकार: | क्रिम्प/सोल्डर |

| आवेदन: | औद्योगिक स्वचालन | लिंग: | मूग |

| प्रमुखता देना: | Gold-plated Servo Motor Connector,Moog Gender PCB Connector,1000V SCSI Connector |

||

Gold-plated SCSI soldering board female socket bent pins 14 20 26P PCB connector 36-pin 50P plug servo connector

![]()

![]()

Product Description:

The Servo Motor Connectors are specifically engineered to meet the demanding requirements of industrial automation systems, providing reliable and efficient connectivity solutions for a wide range of servo motor applications. Designed with a robust voltage rating of 1000V, these connectors ensure safe and stable electrical performance even in high-voltage environments, making them an ideal choice for critical industrial operations.

One of the standout features of these connectors is their compatibility with Moog gender configurations, which are widely recognized in the servo motor industry for their precision and durability. This ensures seamless integration with Moog servo motor components, facilitating easy installation and maintenance. Their sturdy construction is designed to withstand harsh operating conditions, with an impressive temperature range from -40℃ to +105℃, allowing them to function reliably in extreme environments without compromising performance.

These connectors are particularly well-suited for applications involving Electro Hydraulic Servo systems, where precise control and responsiveness are paramount. The connectors facilitate the transmission of signals and power between the servo motor and its control unit, ensuring the smooth operation of Electro Hydraulic Servo mechanisms. This makes them an essential component in machinery that relies on hydraulic actuation combined with electronic control for enhanced accuracy and efficiency.

In addition to Electro Hydraulic Servo applications, these connectors are compatible with DC Servo Motor Drive systems. DC servo motors are known for their high torque and precise control capabilities, often used in automation equipment and robotic systems. The connectors provide reliable electrical connections that support the current requirements of DC servo motors, ensuring consistent performance and reducing downtime caused by connection failures.

Hydraulic Brake Motors also benefit from the use of these servo motor connectors. Hydraulic brake motors require robust and dependable connectors to handle the electrical demands of the braking system while withstanding the mechanical stresses involved. The connectors’ design supports the current rating necessary for battery-powered hydraulic brake motors, ensuring that these critical safety components operate with maximum reliability.

The current rating of these connectors is optimized to support battery-powered applications, reflecting their versatility in modern industrial automation setups where battery usage is increasingly common. This feature ensures that the power delivery to the servo motor is stable and sufficient, preventing power loss and enhancing the overall efficiency of the system.

Overall, the Servo Motor Connectors represent a high-quality, dependable solution for connecting servo motors in various industrial automation environments. Their high voltage rating, wide operating temperature range, and compatibility with Moog gender standards make them suitable for a broad spectrum of applications, including Electro Hydraulic Servo systems, DC Servo Motor Drives, and Hydraulic Brake Motors. By ensuring secure and stable electrical connections, these connectors help maintain the performance and safety of automation equipment, contributing to increased productivity and reduced maintenance costs.

Features:

- Product Name: Servo Motor Connectors

- Current Rating: Battery

- Insulation Resistance: 10PIN

- Application: Industrial Automation

- Wire Gauge: 18-24 AWG or more, AWG 3-12 Diameter

- Mounting Type: Panel Mount / Cable Mount

- Compatible with Hydraulic Brake Motors

- Suitable for Brushless Servo Motor applications

- Ideal for High Torque DC Servo Motor systems

Technical Parameters:

| Material | Metal/Plastic |

| Mounting Type | Panel Mount/Cable Mount |

| Number of Contacts | Omrons Domestic |

| Contact Plating | Silver Pin, Golded Pin |

| Operating Temperature | -40℃ To +105℃ |

| Insulation Resistance | 10PIN |

| Name | Moog ITT Connector |

| Wire Gauge | 18-24 AWG Or More, AWG 3-12 Diameter |

| Gender | Moog |

| Current Rating | Battery |

Applications:

The NO MARK servo motor connector, model number servo motor connector, is a high-quality and reliable solution designed specifically for industrial automation applications. Manufactured in China and certified with CE and ISO9001 standards, this connector ensures safety and performance in demanding environments. With a voltage rating of 1000V and contact plating options including silver and gold-plated pins, it guarantees excellent conductivity and durability, crucial for precise and efficient operation of servo motors.

This servo motor connector is widely used in conjunction with AC servo motor drivers and brushless servo motors, making it an essential component in modern automation systems. Its versatile mounting types, including panel mount and cable mount options, allow for flexible installation in various industrial setups. Whether it is integrated into robotic arms, CNC machines, or automated assembly lines, the connector facilitates secure and stable electrical connections, ensuring uninterrupted power and signal transmission to servo motors.

Ideal for applications involving AC servo motor drivers, the connector supports high-speed communication and power transfer, improving the overall responsiveness and accuracy of motor control systems. Its robust design and reliable contact plating reduce the risk of signal loss and electrical interference, which are common challenges in fast-paced industrial environments. This makes it suitable for use in precision machinery, packaging equipment, and other automated production lines where consistent performance is critical.

With a supply ability of 1000 pieces per day and a minimum order quantity of 100 units, the NO MARK servo motor connector is readily available for large-scale industrial projects. The products are packaged securely in carton boxes to ensure safe delivery within 1-3 working days. Payment terms are flexible, supporting T/T and PayPal for customer convenience. Overall, this servo motor connector is an excellent choice for industries seeking reliable and efficient connections for AC servo motor drivers and brushless servo motors, boosting productivity and system stability.

Customization:

Our Servo Motor Connectors, branded as NO MARK and model number servo motor connector, are designed to meet the highest standards with certifications including CE and ISO9001. Originating from China, these connectors are ideal for applications involving AC Brushless Servo Motors, AC Servo Motor Drivers, and Hydraulic Brake Motors.

Featuring a current rating suitable for battery applications, the connectors support a voltage rating of 1000V and offer excellent insulation resistance with a 10PIN configuration. They operate efficiently within a temperature range of -40℃ to +105℃, ensuring reliable performance in various environments.

The termination type is available in both crimp and solder options, providing flexibility for diverse installation requirements. We maintain a strong supply ability of 1000 pcs/day, with a minimum order quantity of 100 units. Packaging is handled securely in carton boxes to ensure safe delivery.

Our delivery time is swift, typically between 1-3 working days, and we accept payment terms including T/T and PayPal, making transactions convenient and secure for our customers.

Support and Services:

Our Servo Motor Connectors are designed to provide reliable and secure connections for servo motor applications. They ensure optimal electrical performance and durability in various industrial environments.

For technical support, please refer to the product datasheet and installation manuals available on our website. These documents include detailed specifications, wiring diagrams, and troubleshooting tips to help you install and maintain your connectors efficiently.

We offer comprehensive services including connector customization, compatibility consultation, and lifecycle support to meet your unique project requirements. Our technical team is equipped to assist with product selection, system integration, and performance optimization.

Regular maintenance and inspection of the connectors are recommended to ensure long-term reliability. Avoid exposure to extreme environmental conditions and mechanical stress to prevent damage and ensure consistent operation.

For software and firmware updates related to servo motor control systems, please check our online resources. We provide manuals, FAQs, and instructional videos to facilitate smooth operation and problem resolution.

Should you encounter any issues beyond the provided documentation, our technical experts are available to guide you through advanced troubleshooting and repair procedures to minimize downtime and maintain system efficiency.

व्यक्ति से संपर्क करें: Zhou

दूरभाष: +8613316962478

-

ASD-MDBT0100 सर्वो मोटर कनेक्टर्स

-

M23 M40 E P प्रकार के सर्वो मोटर केबल कनेक्टर 17 पिन 12 पिन

-

SM-6E 6E SM सर्वो कनेक्टर्स पूर्ण सेट IEEE1394 6 कोर महिला भागों

-

सर्वो SM-6P MOLEX SM6P 1394 6PIN पुरुष महिला कनेक्टर

-

J17S-06FMH-7KL-1M-CF PA66 सर्वो मोटर कनेक्टर्स स्प्रिंग स्टेल के साथ

-

All-gold SCSI Connector 20/26/50-pin 50P Plug for Servo Motor with Moog ITT Compatibility